OUR INFRASTRUCTURE

We are one of the leading manufacturers in Tirupur, India. All our manufacturing units are spread across multiple

parts of Tirupur with vertically integrated infrastructure & traceable supply chain process, which ensures complete

control over the process and quality control

Our vertically integrated manufacturing facility ensures that every step of the supply chain, from recycled fibers into

yarn to sewing the finished product which takes place in the same facility. Managing the supply chain and having

everything under they v one roof allows us to deliver superior quality with quick leads. We also significantly minimize

our carbon footprint by eliminating transportation throughout our supply chain.

OUR INFRASTRUCTURE

We are one of the leading manufacturers in Tirupur, India. All our manufacturing units are spread across multiple parts of Tirupur with vertically integrated infrastructure & traceable supply chain process, which ensures complete control over the process and quality control

Our vertically integrated manufacturing facility ensures that every step of the supply chain, from recycled fibers into yarn to sewing the finished product which takes place in the same facility. Managing the supply chain and having everything under they v one roof allows us to deliver superior quality with quick leads. We also significantly minimize our carbon footprint by eliminating transportation throughout our supply chain.

KNITTING UNIT

Our in-house knitting capacity is 20 tons per day with our vertically integrated infrastructure which ensures shorter lead time, quick processing, easy source of raw materials, and assured quality which has created a name by itself in the industry.

KNITTING UNIT

Our in-house knitting capacity is 20 tons per day with our vertically integrated infrastructure which ensures shorter lead time, quick processing, easy source of raw materials, and assured quality which has created a name by itself in the industry.

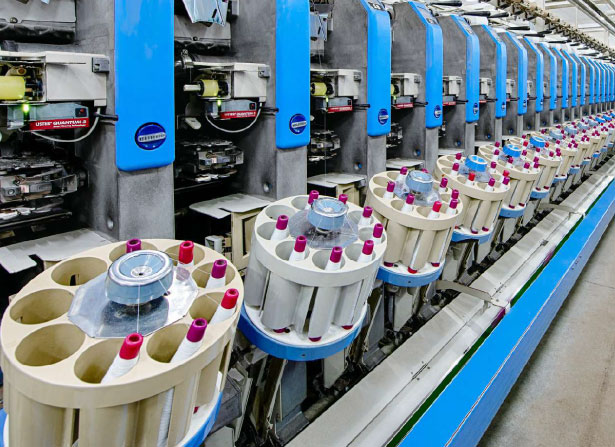

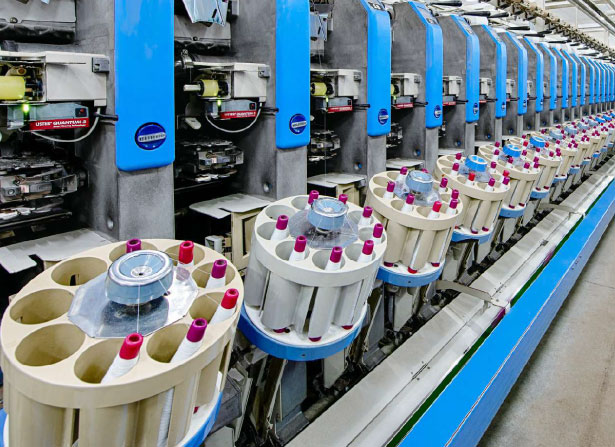

SPINNING UNIT

We produce 80 tons of melange yarn per day with a capacity of 1,60,000 spindles which makes us one of the largest melange yarn manufacturers in India. We have almost 10k shades with various combinations of innovative & sustainable fibers. We have 60 never-out-of-stock shades at any given time with no predefined MOQ and a shorter lead time.

SPINNING UNIT

We produce 80 tons of melange yarn per day with a capacity of 1,60,000 spindles which makes us one of the largest melange yarn manufacturers in India. We have almost 10k shades with various combinations of innovative & sustainable fibers. We have 60 never-out-of-stock shades at any given time with no predefined MOQ and a shorter lead time.

DOPE DYEING UNIT

Our vertically integrated RPSF plant use the dope – dyed method in the production of recycled polyester fibre and effectively uses almost zero percentage of water in the process. We are the first company worldwide to receive an LCA report on dope dyeing for the RPSF process.

DOPE DYEING UNIT

Our vertically integrated RPSF plant use the dope-dyed method in the production of recycled polyester fibre and effectively uses almost zero percentage of water in the process. We are the first company worldwide to receive an LCA report on dope dyeing for the RPSF process.

RECYCLING UNIT

The recycling unit works to transform post-industrial textile waste into valuable and high-quality recycled cotton fibers. We recycle cotton end bits used in our garment factory and create a circular system where the waste of today becomes the raw material of tomorrow.

RECYCLING UNIT

The recycling unit works to transform post-industrial textile waste into valuable and high-quality recycled cotton fibers. We recycle cotton end bits used in our garment factory and create a circular system where the waste of today becomes the raw material of tomorrow.

GARMENTING UNIT

We produce 3.5 – 550K pieces of garments every month. We have built a full-fledged enterprise with all the necessary skills to manufacture any type of knitted garment with a variety of fabrics and styles products for kids and adults, across all categories of knits.

GARMENTING UNIT

We produce 3.5 – 550K pieces of garments every month. We have built a full-fledged enterprise with all the necessary skills to manufacture any type of knitted garment with a variety of fabrics and styles products for kids and adults, across all categories of knits.

SLEEPSTER UNIT

Our RPSF plant also produces fiber used for various other industries. The hollow conjugated fibers are used for pillow fills known for their superb resilience and bounciness. As an extended brand portfolio Sleepstar uses all recycled polyester fiber fillings in mattress, pillows and is one of the first company in India to use polyester fibre blocks in making mattresses.

SLEEPSTER UNIT

Our RPSF plant also produces fiber used for various other industries. The hollow conjugated fibers are used for pillow fills known for their superb resilience and bounciness. As an extended brand portfolio Sleepstar uses all recycled polyester fiber fillings in mattress, pillows and is one of the first company in India to use polyester fibre blocks in making mattresses.

20 Tons

in-house knitting

machines with a knitting

capacity of 20 tons/day

8 Million

Recycle PET bottles

every day, 140 Tons

RPSF/day

1,60,000

Spindles 80 tons of

melange & raw

yarn/day

3.5-550K

Garments

production

per month