Spinning the wheel of Sustainable Change

Spinning the wheel of Sustainable Change

What if we could make the earth a better place to live in, for our future generations? What if we could recycle plastic and turn it into something better and more sustainable? Our future – and our children’s future -depends on it.

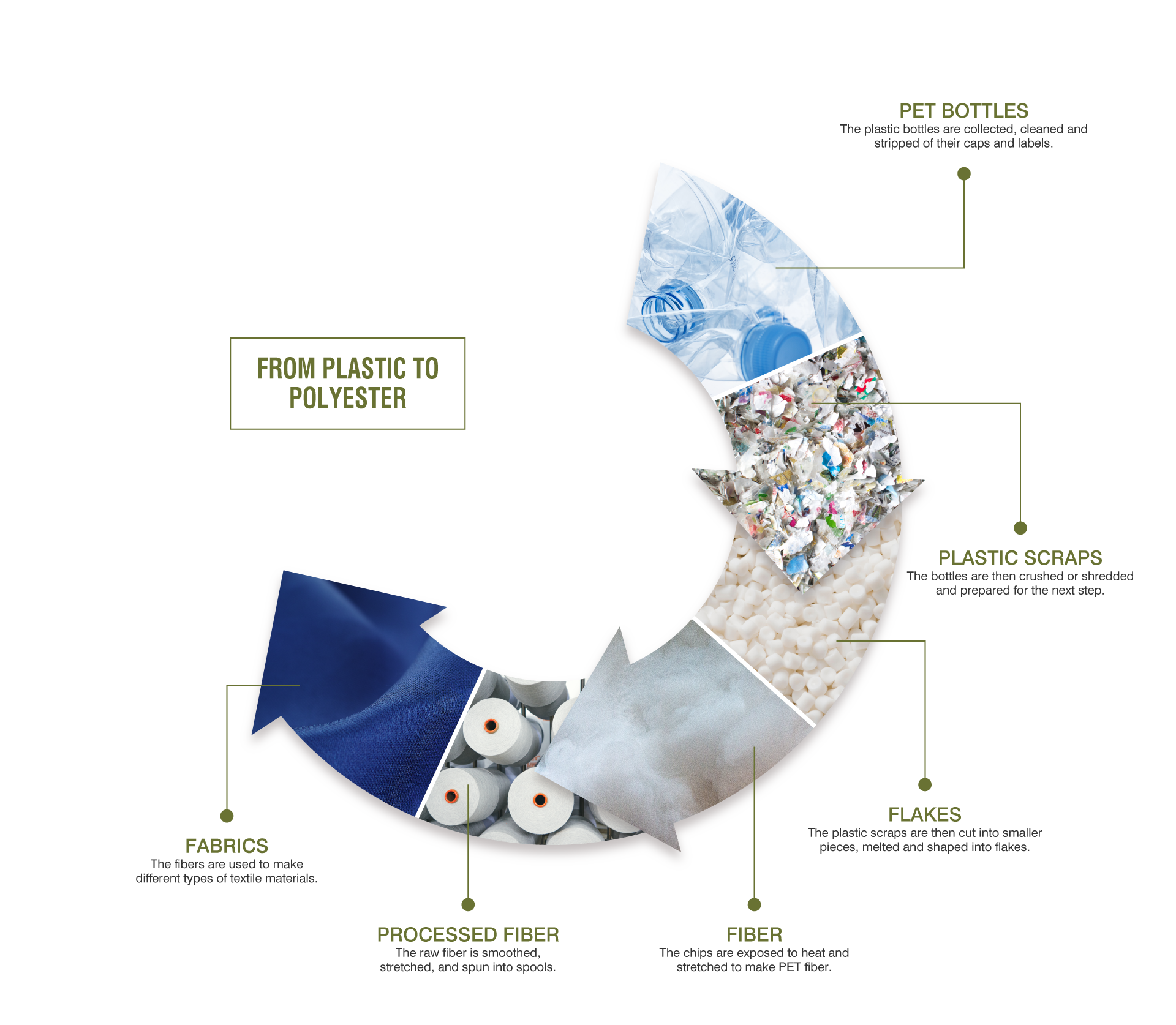

At Sulochana, we love sustainability so much, we collect our own plastic bottles and feed them into our vertically integrated process to create recycled polyester. This, in turn, can be used to create beautiful, sustainable products such as filament, staple fiber and fiberfill products. Here’s the simple math -the more plastic we recycle, the less chance it has to end up either in landfills or as plastic littering our landscape and oceans.

RECYCLED POLYESTER YARN

Eco-Friendly

Food, clothing, and shelter (by extension, our environment) are basic necessities for a comfortable life. The choices we make on these domains can never be compromised. Give your clothes a new life without harming the planet by replacing the traditional yarn with our unique, eco-friendly, sustainable yarns made from recycled PET bottles. With the help of advanced technology, Sulochana Mills’ in-house brand Ecoespin coverts plastic bottles into fibre which in turn can translate into everyday or designer clothes.

Eco-Friendly

Food, clothing, and shelter (by extension, our environment) are basic necessities for a comfortable life. The choices we make on these domains can never be compromised. Give your clothes a new life without harming the planet by replacing the traditional yarn with our unique, eco-friendly, sustainable yarns made from recycled PET bottles. With the help of advanced technology, Sulochana Mills’ in-house brand Ecoespin coverts plastic bottles into fibre which in turn can translate into everyday or designer clothes.

Fashion

It has been estimated that approximately 10% of the global carbon emissions come from the fashion industry. That’s more than international flights and maritime shipping combined. However, the shift towards sustainability will be a game changer. Recycled polyester reduces our dependence on petroleum raw materials, it takes less energy to manufacture it as compared to virgin polyester and the use of PET bottles reduces the stress on overburdened landfill, ultimately decreasing soil, air and water pollution.

Fashion

It has been estimated that approximately 10% of the global carbon emissions come from the fashion industry. That’s more than international flights and maritime shipping combined. However, the shift towards sustainability will be a game changer. Recycled polyester reduces our dependence on petroleum raw materials, it takes less energy to manufacture it as compared to virgin polyester and the use of PET bottles reduces the stress on overburdened landfill, ultimately decreasing soil, air and water pollution.

Applications

Our superior quality fabrics blends can be customized as per your needs and preference. The fully finished staple fiber is used for ring and/or open-end spinning, woven, non-woven and home furnishing applications.

Knitting

Sweater

Woven

Types of polyester produced

1. Recycle polyester staple fiber

- Raw white polyester staple fibers

- Dope dyed polyester staple fibers

2. Technical/ industrial textile

- Polyester flame retardant

- Polyester antimicrobial fiber

- Polyester fiber fillings

- Non-woven fibers

- Hollow conjugated fibers

3. TOW

4. Low Pilling

5. Cotton Alike

6. Cationic Fibers

THE PROCESS

PRODUCT SPECIFICATIONS

| Semi Dull (Cotton look) Fibre | Dope Dyed BLACK Fibre | Optic White Fibre | Dope Dyed COLOUR Fibre |

|---|---|---|---|

| Denier : 1.2, 1.4 | Denier : 1.2, 1.4 | Denier : 1.2, 1.4 | Denier : 1.2 |

| Cut length : 32, 38, 44, 51 mm | Cut length : 32, 38, 44, 51 mm | Cut length : 32, 38, 44, 51 mm | Cut length : 32, 38, 44, 51 mm |

| Fibre Specifications | Fibre Specifications | Fibre Specifications | Fibre Specifications |

| DPF : 1.35 - 1.45 | DPF : 1.38 - 1.45 | DPF : 1.35 - 1.45 | DPF : 1.38 - 1.45 |

| Tenacity (gpd) : 5.5 - 6.0 | Tenacity (gpd) : 5.4 - 5.8 | Tenacity (gpd) : 5.4 - 5.9 | Tenacity (gpd) : 5.2 - 5.6 |

| Elongation % : 17 - 23 | Elongation % : 17 - 23 | Elongation % : 17 - 23 | Elongation % : 17 - 23 |

| Oil pickup : 0.20 - 0.25 | Oil pickup : 0.20 - 0.25 | Oil pickup : 0.20 - 0.25 | Oil pickup : 0.20 - 0.25 |

| Semi Dull (Cotton look) Fibre | Dope Dyed BLACK Fibre |

|---|---|

| Denier : 1.4, 1.7 | Denier : 1.4, 1.7 |

| Cut length : 32, 38, 44, 51 mm | Cut length : 32, 38, 44, 51 mm |

| Fibre Specifications | Fibre Specifications |

| DPF : 1.35 - 1.45 | DPF : 1.38 - 1.45 |

| Tenacity (gpd) : 5.5 - 6.0 | Tenacity (gpd) : 5.4 - 5.8 |

| Elongation % : 17 - 23 | Elongation % : 17 - 23 |

| Oil pickup : 0.20 - 0.25 | Oil pickup : 0.20 - 0.25 |

| Optic White Fibre | Dope Dyed COLOUR Fibre |

|---|---|

| Denier : 1.4, 1.7 | Denier : 1.4 |

| Cut length : 32, 38, 44, 51 mm | Cut length : 32, 38, 44, 51 mm |

| Fibre Specifications | Fibre Specifications |

| DPF : 1.35 - 1.45 | DPF : 1.38 - 1.45 |

| Tenacity (gpd) : 5.4 - 5.9 | Tenacity (gpd) : 5.2 - 5.6 |

| Elongation % : 17 - 23 | Elongation % : 17 - 23 |

| Oil pickup : 0.20 - 0.25 | Oil pickup : 0.20 - 0.25 |

SULOCHANA COLOUR FIBRES

OUR CONCERN

LESS POLLUTION, BETTER OUTPUT

Sulochana Spinning Mills uses the dope-dyed method in its production of recycled polyester fibre. Dope dyeing is the process of injecting colours/pigment at the stage of the dope when the cellulosic material is in semi liquid stage.

The cellulosic textile industry consumes a huge quantity of water in wet processing operations like desizing, scouring, mercerizing, bleaching and dyeing employed during conversion of fibre to fabric. During the last decade, the serious concern about environmental issues has grown drastically, which has increased many folds, because of increasing industrial pollution, waste problems, effects of global warming, etc.

Therefore, DOPE DYED is the right solution to reduce the pollution and wastewater discharges in a textile processing factory to the environment.

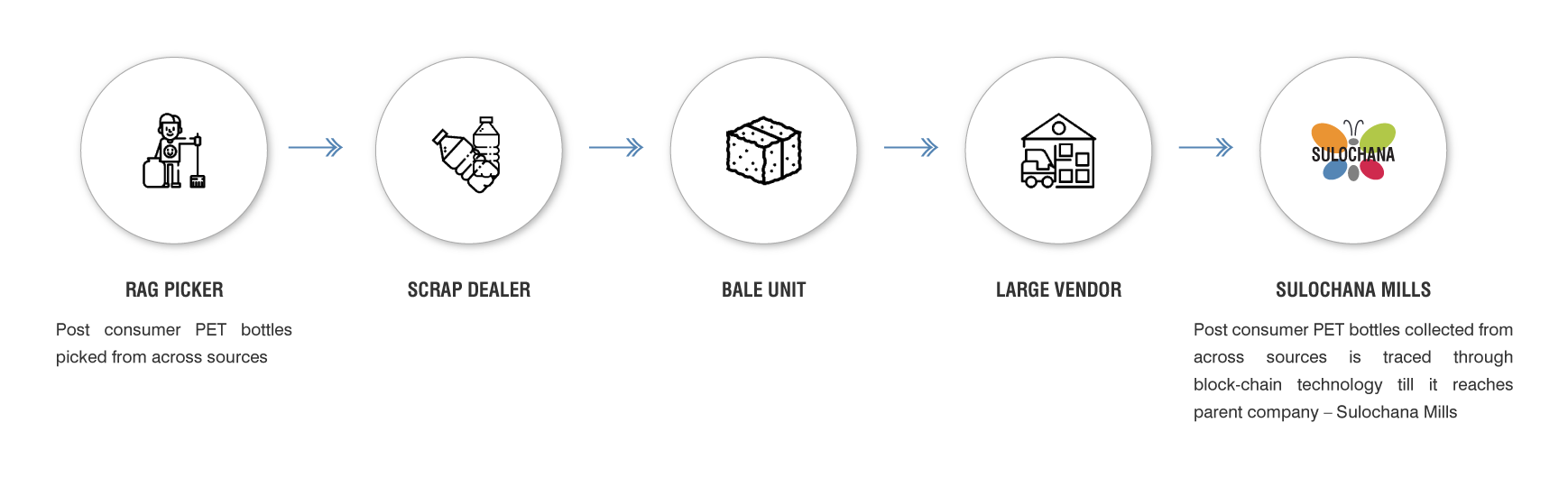

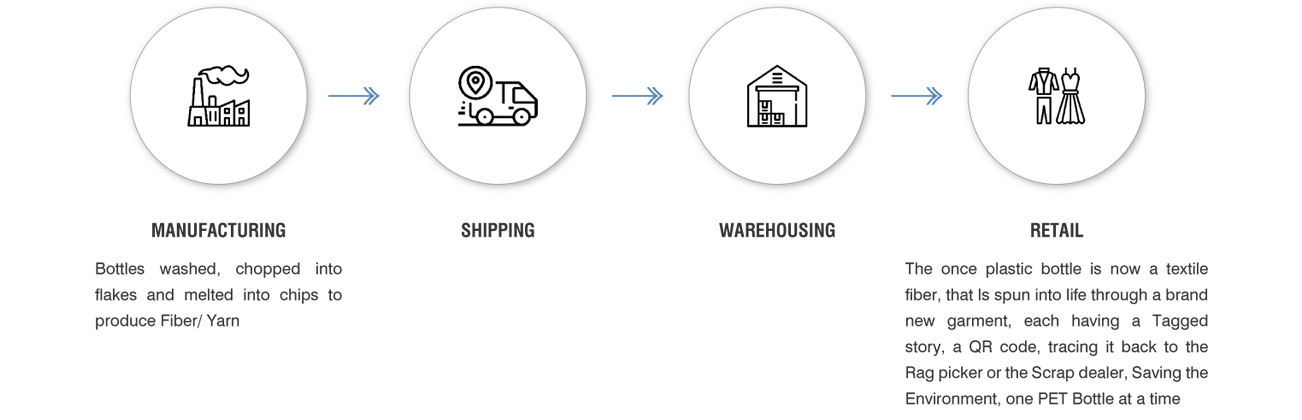

BOTTLE TO SHELF

Sulochana Mills is a socially and environmentally conscious company that produces over 200 tons of yarn and fibre in a day. Our Bottle-to-Shelf technology helps recycle 8 million PET bottles every day to into 140 tons of RPSF per day using dope dyeing technique to use zero percentage of water.

WHAT WE DO

WE ARE HERE TO SOLVE A PROBLEM.

BUT, WHAT EXACTLY IS THE PROBLEM?

Its little help to the environment if these clothes are soon thrown away, along with the 11million tons of clothes that are trashed each year.

8 million metric tons of plastic enter the ocean every year, on top of the estimated 150 million metric tons that currently circulate in marine environments.

After its initial use, over 60% of the total plastic solid waste (PSW) produced is discarded in landfills throughout the world. Less than 10% of plastic waste is recycled

RECYCLE YOUR PET BOTTLE? #WHYNOT

It takes 2,700 litres of water to make a single cotton T-shirt. When this T-shirt is made of recycled PET bottle, it requires 8 such bottles. The math is simple here!

When you opt for a T-shirt made of recycled PET, you can save 2700 litres of water & 8 PET Bottles from landfill. A small decision of yours can save water consumption by 90%. Plastics in the ocean is a huge problem for the biodiversity and ocean creatures. One purchase decision of yours can make this a better planet.

Save the Planet One Bottle at a time!

- Our promise is to use materials that are sustainable, recycled or which go to waste.

- A 100% sustainable & recycle clothing brand with planet first approach.

- We embarked on this journey to make a change and we believe in the principle of 3R’s-Reduce, Reuse and Recycle

TRACEABILITY FEATURES OF

OUR BOTTLE-2-SHELF TECHNOLOGY

CERTIFICATIONS